Engineering Capabilities

Electro Mechanical Design

- Electromagnetic design using FEA

- Optimization through simulation based design

- Mechanical design

- DFMEA at System/Subsystem/Component Level

Systems Engineering

- Requirements Management

- System Safety Analysis

- System Function Development

- Calibration and Variants Management

- Mechanical and Thermal Design

Software Engineering

- Stack Integration

- Software Architectural Design

- Safe and Secure coding Practices

- Modular SW Module Development

- OS and Bootloaders

- (Model Based & Hand Coding)

Testing & Validation

- Test Management

- Test Automation

- Qualification Test

- Unit & Integration Test

- HiL & Vehicle Test

- Test Specification and Design

Electronics Engineering

- Small Footprint & Low Power Design

- Schematic Design &PCB Layout

- Power Integrity & Thermal Analysis

- Power Electronics

- Qualitative and Quantitative Safety Analysis with Metrics

- Worst Case Analysis

Process & Quality

- Organizational Specific Quality Process

- ASPICE Compliant Development

- Agile Development Process

- IATF Certified

- Evita Low Security Compliance

- Expertise in Functional Safety

R&D Capabilities

Our state of the art R&D facilities are spread across the Chennai, Hosur and Pudhucherry locations, with over 300 engineers working in different domains and serving different value streams including 5 stage – Gate product development process, design reviews with design and process FMEA and design for manufacture to focus on cost optimization

Lucas TVS group has 22 granted patents and few more under examination awaiting publication.

Our R&D capabilities

Electrical

Design

Mechanical & Structural

Design

Electronics Hardware

Design

Software

Interfacing

Fluid Flow

Dynamics

Thermal

Analysis

Cogging Torque

Optimisation

System Simulation &

Snalysis

Reliability Growth

Management

Statistical

Analysis

Product Functional

Test

Validation

Test

Reliability

Test

Durability

Test

Our R&D Testing Facilities

Radiography Machine

Thermal Shock Chamber

Endurance chamber

Transient Pulse Tester

Thermo Cyclic Chamber

Radiated Susceptibility

Other Testing Facilities

- Thermal cycling test

- Endurance test

- Efficiency test

- Water spray test

- Humidity test

- High Speed test

- Salt spray test

- Thermal Fatigue test

- Vibration test

- Radiated Susceptibility test

- Cold cranking test

- Performance test at hot and cold condition

Product Validation Facilities

Product

Design

Product

Development

Prototype

Manufacturing

Product Proving

/ Reliability Engineering

Tool

Design

Advanced

Engineering

Manufacturing Technology

/ Development

Materials / Process

Development

Plant / Spm Manufacturing

Technology

Testing & Quality Inspection

Combined Vibration and

Environmental Testing Equipment

Cold Room

Climatic Chamber

Salt Mist Chamber

NVH

Test Lab

Engine Room

– Starter Durability

Mud Wading

Test Track

Compressor Motor

– Life Testing Equipment

Combined Bi-Axial Vibration & Environmental Test Equipment

3 Zone Thermal

Shock Chamber

Water Wading

Test Track

Carl Zeiss Coordinate

measuring machine

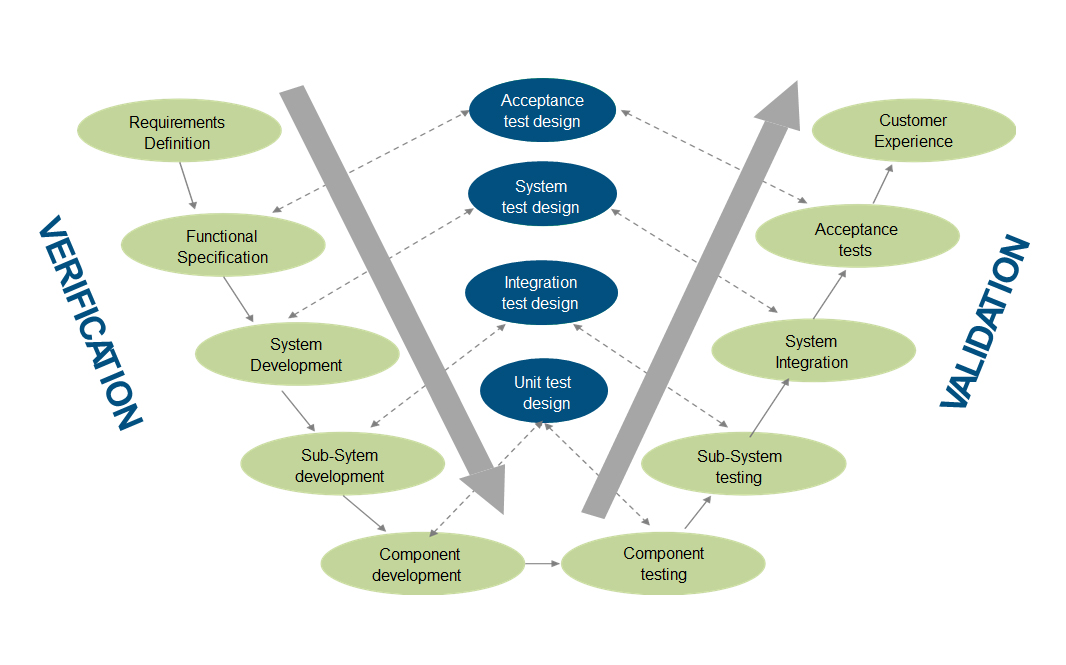

V-Model Development Approach

Electronics Design & Production

Electronic Design Capabilities

Analog & Digital

Circuit

PCB Design using

Orcad & Zuken

LDRA Static & Dynamic

Code Analyzer

ECU Software

Tuning

Embedded Control

System Design

Multi Layer

PCB Design

Product Reliability

Testing

Failure Analysis &

Simulation

Production Capabilities

Our Subsidiary company is equipped with 3 SMT assembly lines with ESD controls located in Hosur & Puducherry units with a combined capacity of over 180,000 chip shooters. Flexible manufacturing assembly lines can handle both small volume as well as large volume variants.

Pick & Place Assembly Line

Screen Printer

N2 Reflow Oven

Chip Shooter, Fine Pitch Placer

Wave Soldering Machine

SMT Line

Facilities

- Screen printer

- Chip shooter, Fine pitch placer

- Reflow oven – 9zones with N2 atmosphere

(capability for Lead-free soldering)

- Automated optical inspection

- Wave soldering machine

- Assembly lines & Potting facility

- Dedicated EOL test equipments

LTVS capabilities – Electronics Design & production

SMT Liner

SMT Line

Robotic Soldering Assly Line

Auto Coil Winding Line

SMT Line

3D Solder Paste Inspection

High Vacuum Potting Line

Rotor Assembly Line

Automatic Optical Inspection

Pick & Place Machine Latest Model

PCBA/Product Assembly Line

Lead-Free Wave Soldering Machine

PC based EOL Testing with Data Logging

LED PCBA Test Equipment with Data Logging

End of Line Tester with Spark Angle Vision Cotrol

Three Axes Robot Soldering with Auto Clean

Angle Sensor Calibration & Programming System

PC based Vision Control Micro Chip Flasher

Automated Spot-Welding Machine

Ignition Coil Testing Machine with Waveform Comparator

In-house Machine Building Centre

Organization Skill Sets

- Mechanical Design

- Electrical & Electronics Design

- Controls & software

- Material & Vendor Development

- Machine building

- Assembly, Testing & Installation

Capability to Design & Manufacture

- Assembly Machines

- EOL Test Rigs

- Assembly lines

- Armature manufacturing lines

- Stator manufacturing lines

- Process Plants

- Welding SPM

- Metal Cutting SPM

Team : 50 Area: 15000 sq.ft

Hard Turning SPM

Stator Coil Winding SPM

Wiper Performance Test Rig

Core taping SPM

Starter Motor Assembly Line

LTVS Manufacturing Capabilities

Advanced Tool Room/Precision Manufacturing Facilities

Proto Type Manufacturing

Winding Machine

Precision Grinding

EDM Sparking Machine

General manufacturing

Press Shop

Plating

Heat Treatment

Varnishing Machine

Curing Oven

Accurate CNC Machining

Three Nozzle Internal Winding Machine

Shrink Fitting Machine

LTVS Manufacturing Capabilities

Varnishing Machine

Automatic Balancing Machine

Shaft Pressing SPM

Automatic Noise Testing

Automatic Wiper Armature – Assembly Line

Conveyorized Automatic Armature Line (RFID Technology)

Conveyorized Starter Motor Assembly Line

Commutator Turning Machine

LTVS – The Solution Provider

Anticipate

Understanding the need of customers and end users and developing and proving the concept in advance.

Innovate

Mechatronic Motion control expertise –Motor ,Embedded Electronics ( Software and Hardware ), mechanical design and development expertise that helps build relevant complex solution parts/products to meet

Improve

State of the art validation process supported by industry leading tools & Continuous improvement process

Execution

System and design expertise backed by robust engineering processes along with proven structured manufacturing processes that help to deliver exceptional products to market